BIM For Fabrication

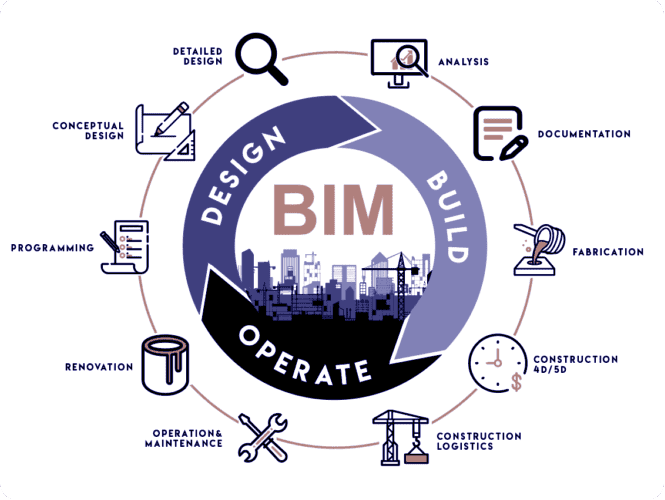

In the dynamic landscape of modern construction, the role of Building Information Modeling (BIM) for fabrication services cannot be overstated. This cutting-edge technology is reshaping the way we approach construction projects, providing efficiency, accuracy, and a streamlined process from inception to completion.

Embracing BIM: A Game-Changer for Fabrication

In the ever-evolving construction industry, embracing BIM for fabrication services is a game-changer. This innovative approach integrates 3D modeling and intelligent data to enhance collaboration, communication, and overall project management.

Fabrication Services in Construction:

Fabrication services play a crucial role in the construction supply chain, encompassing the creation of structural elements, components, and assemblies. These services involve the transformation of raw materials into finished products, which are integral to the construction process.

Integration of BIM and Fabrication:

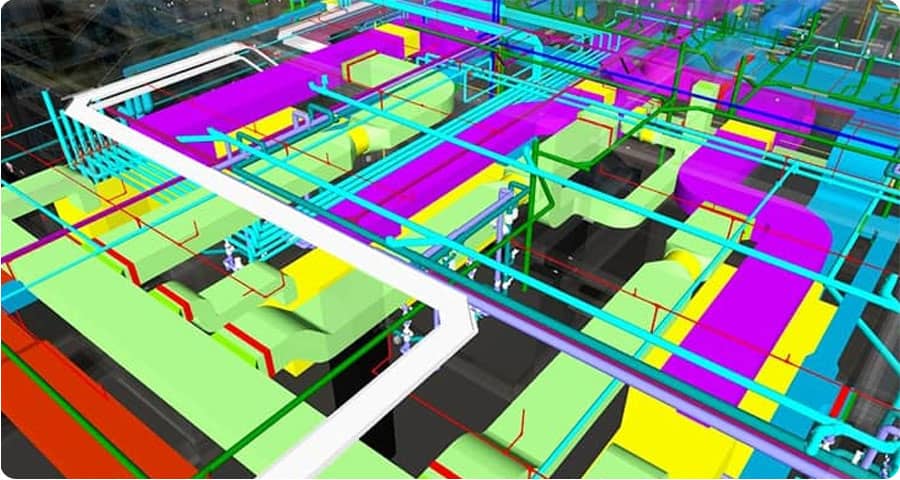

BIM for fabrication services involves the creation and utilization of detailed 3D models that encompass every aspect of the fabrication process. This integration allows for seamless collaboration between architects, engineers, and fabricators, ensuring accuracy and efficiency in the production of building components.

Unveiling the Benefits of BIM in Fabrication

- Precision in Planning: BIM allows for meticulous planning by providing a detailed 3D representation of the entire project. This not only aids in visualizing the final outcome but also ensures precise measurements and accurate material estimates.

- Enhanced Collaboration: The collaborative nature of BIM fosters seamless communication among various stakeholders, from architects to engineers and fabricators. This real-time collaboration minimizes errors, reduces delays, and ensures everyone is on the same page throughout the fabrication process.

- Improved Efficiency: Efficiency is paramount in fabrication services, and BIM delivers just that. By streamlining workflows and optimizing resource allocation, projects are completed more swiftly without compromising quality. Time is money, and BIM helps save both.

Harnessing the Power of BIM: A Step Towards Sustainable Fabrication

In a world increasingly focused on sustainability, BIM plays a pivotal role in promoting eco-friendly fabrication practices. The ability to simulate and analyze energy consumption, material usage, and waste generation empowers stakeholders to make informed decisions that align with environmental goals.

Investing in the Future: BIM for Fabrication Services

As the construction industry marches towards digitization, investing in BIM for fabrication services is not just an option; it is a strategic move towards staying competitive and relevant. The advantages are clear which are increased accuracy, reduced costs, and accelerated project timelines.

Making the Shift: Implementing BIM in Your Fabrication Projects

- Training and Adoption: To fully capitalize on the benefits of BIM, investing in training for your team is crucial. Equip your workforce with the necessary skills to navigate BIM software, ensuring a smooth transition and optimal utilization.

- Integration with Existing Systems: Integrating BIM seamlessly with your existing fabrication processes is key. Choose software solutions that complement your current workflow, minimizing disruptions and maximizing efficiency.

Why Choose Our BIM Fabrication Services?

- Expertise and Experience: Our team comprises seasoned professionals with extensive experience in both BIM and fabrication services. We bring a wealth of knowledge to every project, ensuring a high level of expertise in utilizing BIM for precise and efficient fabrication processes.

- Cutting-Edge Technology: We stay at the forefront of technological advancements in both BIM and fabrication tools. By leveraging the latest software and hardware solutions, we provide our clients with state-of-the-art services that adhere to industry standards and best practices.

- Customized Solutions: Recognizing that each project is unique, we tailor our BIM fabrication services to meet the specific requirements of our clients. Our approach is flexible, allowing us to adapt to varying project scales, complexities, and objectives.

- Commitment to Quality: Quality is at the core of our services. Through rigorous quality control processes and adherence to industry standards, we ensure that the fabricated components meet or exceed the specified requirements, contributing to the overall success of the construction project.

- Cost-Effective Solutions: We understand the importance of cost efficiency in construction projects. By employing BIM for fabrication, we optimize processes, minimize wastage, and enhance productivity, ultimately delivering cost-effective solutions without compromising on quality.

Future-Proofing Your Fabrication Business

In a rapidly evolving industry, future-proofing your fabrication business is imperative. BIM not only addresses current challenges but also positions your company as a forward-thinking entity ready to embrace innovations that redefine the standards of excellence.

Conclusion: Embrace the Future of Fabrication with BIM

In conclusion, the era of BIM for fabrication services is upon us, offering a transformative approach to construction projects. From precise planning to enhanced collaboration and sustainability, BIM is the catalyst for a more efficient, cost-effective, and environmentally conscious future in fabrication. Embrace the revolution, and propel your business into the forefront of modern construction methodologies

By choosing our services, clients can expect a seamless and optimized fabrication process that translates into successful and sustainable construction projects